Arc-Zone® Delivers Best in Class TIG Welding Products, Backed by Industry Leading Technical Service

Knowing how to configure the front end of your TIG torch is essential for arc stability, gas coverage, and weld quality. Collets, collet bodies, gas lenses, and cups allow you to tailor your torch setup to the material, amperage, and access required for the job.

At Arc-Zone.com®, we deliver best-in-class TIG front-end components backed by industry-leading technical support. These parts are selected to help welders achieve consistent results across manual, production, and automation applications.

TIG torch basics

TIG torch models range from 50-amp micro torches to high-amperage automation torches. For manual TIG welding, compact torches that are light and easy to maneuver are preferred. Common manual torch sizes include:

- 9 (2-Series) – 125 A air-cooled

- 17 (3-Series) – 150 A air-cooled

- 20 (2-Series) – 250 A water-cooled (most popular)

Because TIG torches are hand tools, each model is designed for a specific job. Many welders keep two torches on hand— one for everyday work and a specialty torch for tight access or unique setups. If you use a flex torch, keeping a spare torch body available is recommended, as flex necks can wear or fail over time.

Air-cooled vs. water-cooled TIG torches

Air (gas)-cooled torches are simple to install and maintain, making them well suited for jobsites and small shops. They are generally bulkier, limited to about 200 amps, and require cooling time between welds.

Water-cooled torches are compact, easier to handle, and ideal for high-amperage and production welding. They are typically rated up to 500 amps and require either a city water supply or a recirculating water cooler.

Front-end TIG consumables

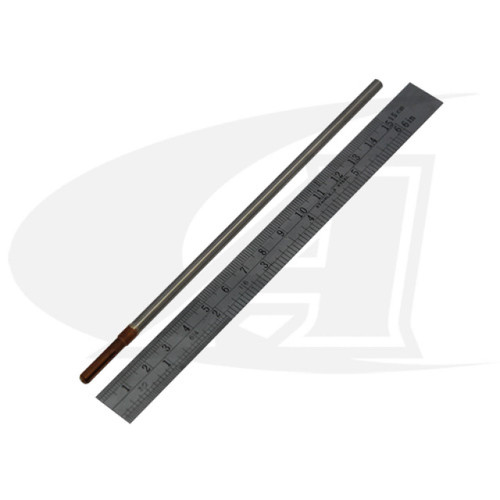

Gas cups, collets, collet bodies, and gas lenses are critical consumables that allow you to customize gas coverage, electrode stick-out, and arc focus. Proper selection helps improve weld appearance and reduce contamination.

Arc-Zone Pro Accessory Kits™ bundle high-quality front-end parts in organized kits with identification cards for easy re-ordering. These kits help save time, reduce downtime, and simplify torch setup.

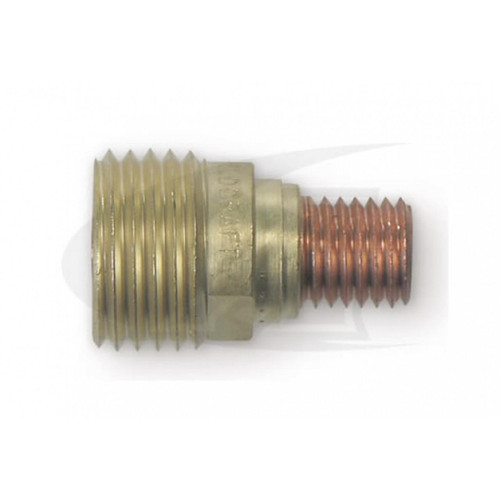

Machine power, water & gas connectors

Note: TIG torch packages typically do not include front-end parts or machine connectors. Power, gas, and water connectors must be ordered separately. If you’re unsure which connectors you need, Arc-Zone.com® technical specialists can help identify the correct components and get your system connected correctly the first time.

How the right front-end setup improves TIG welding

- Improve shielding gas coverage and arc stability

- Support consistent electrode positioning

- Reduce tungsten contamination and rework

- Adapt torch performance to specific applications

Dial in your TIG torch performance with collets, gas lenses, and front-end parts trusted by the pros.

Learn More:

How to Hook Up Your Air-Cooled TIG Torch: PDF

How to Hook Up Your Water-Cooled TIG Torch: PDF

How To Maximize Water-Cooled TIG Performance: PDF

Why Upgrade to a Water-Cooled TIG Torch: PDF

Popular Torch Size Comparison:

9 / 20 (2 Series) & 17 / 18 / 26 (3 Series) Torch Comparison: PDF