Portable band saws are great tools to have on a jobsite, or in your metal fab or hobby shop. If you’re lucky enough to own a new Portaband Pro Band Saw Fixture Kit with a Milwaukee or Dewalt saw, you want to make sure you start with the best blade for the job!

Before you start cutting your way through a quarter inch (1/4″) pipe or a five by five (5” x 5”) piece of material for that matter, it’s important to have the right blade.

How To Determine Which Saw Blade Is Right For You

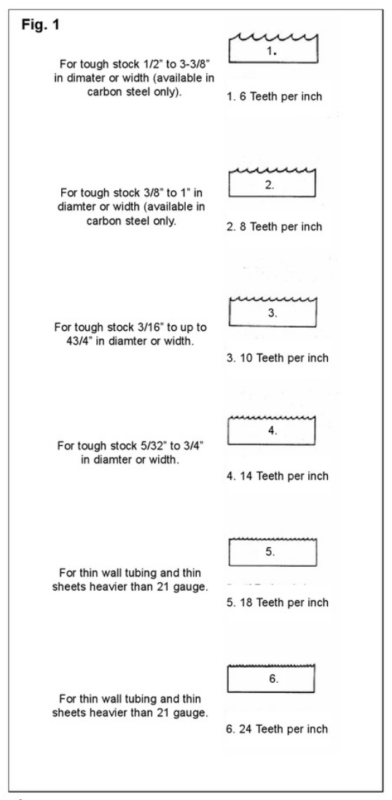

When selecting a band saw blade, start by determining the material being sawed or cut and the Tooth Pitch that is best for that job.

Tooth Pitch refers to the number of Teeth Per Inch (TPI). The relevant variable for selecting the tooth pitch is the contact area of the saw blade in the workpiece being cut.

See FIG.1

Take scroll work, or curved cutting for example. It’s most often performed in the vertical position which works best with a higher tooth count like 14-24 TPI.

When cutting thick wall tubing or bar stock over .125” (1/8″) thickness requires a lower TPI between 8-11 which will cut faster and reduce blade temperature which extends blade life.

For maximum blade life and improved cut quality, JW recommends that you regularly clean and lubricate your blade to reduce heat and extend its life.

Using a cutting lube like LPS Blade & Hole Saw Cutting Tool Lubricant (LPS-43200) will greatly increase the longevity of your saw blades.

For more cutting, grinding, and polishing machines & accessories, visit www.Arc-Zone.com