What constitutes a perfect weld?

Perfection isn’t just about looking good “on the outside.” Perfection is actually difficult to evaluate because a poor quality weld may actually look good on the outside; it’s what you can’t see that can cause the most serious problems.

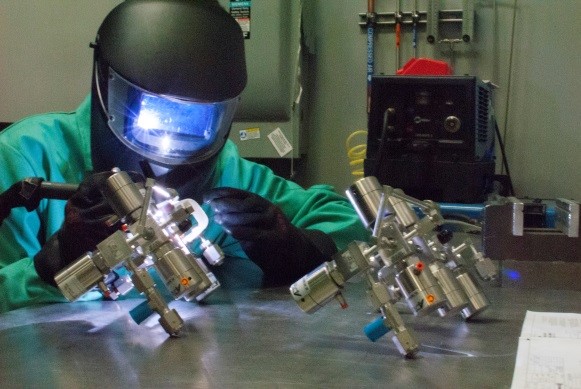

Photo Provided by: Means Engineering

Imperfect welds are undesirable on any job site. But they are unacceptable when the application is process piping for the food and beverage, water treatment, semiconductor, and many other industries. High-purity welding starts with proper preparation and is followed up with highly skilled process pipe and tube fabricators, using the best tools and equipment available.

It wasn’t long ago that you could get away with plugging pipes and tubes with masking tape and cardboard in order to create a dam to fill the tube with inert gas. This process is referred to as purging or back-purging, and it’s critical to shielding the I.D. of the tube from atmosphere. And atmosphere is the enemy of quality, non-porous welds.

Today, there are purpose-built bladders, baffles and dams engineered to help fabricators, jobsite foreman, and welding engineers get repeatable, quality welds and establish welding processes. Add an oxygen monitor that measures contamination down to the PPM, and you’ve got a kit that’s really set-up for success. Collectively, these tools take the guesswork out of the welding process and help the operator deliver consistent, food grade, high purity welds.

What happens if there isn’t good penetration in the weld?

An improper weld can become corroded, allow bacteria to breed, and ultimately create an unsanitary environment. An unsanitary environment can cause a food poisoning outbreak if it occurs in a food processing pipe or container, and goes undetected.

An improper weld can become corroded, allow bacteria to breed, and ultimately create an unsanitary environment. An unsanitary environment can cause a food poisoning outbreak if it occurs in a food processing pipe or container, and goes undetected.

In recent months, several companies have recalled food products due to the outbreak of foodborne illnesses. Sargento [1], the Home of the Real Cheese People, reported a problem in February 2017, when it recalled over 20 of its products after discovering a potential contamination with listeria that originated at one of its supplier’s manufacturing facilities.

While processors maintain high standards for the quality and safety of their products and hold suppliers accountable to the same standards, “things” can literally fall through the cracks. Corrosion is the enemy of the food processing operation; it can cause cracks to develop in the stainless steel tubing and pipes which allows for contamination from various types of bacteria. These cracks often develop from the inside out; therefore, things may look up to par on the outside but on the inside, everything is slowly deteriorating.

Other improper welding techniques that can cause foodborne illnesses include flexing, pits at the end of the welds and stitch or spot welds [3]. Flexing occurs when there is an overlapping of butt welds which causes cracking and allows for contamination. In order to avoid flexing, a butt weld must be ground and polished to the same texture as the contiguous pieces. When pits develop, it is because the weld was terminated too rapidly. Welding is a precise science, it takes patience and extreme focus; it is very important to take the time necessary to ensure complete and safe welds. Additionally, stitch or spot welds, which should be avoided in the food processing industry, cause large gaps in between two pieces of metal. As mentioned before, any gaps or cracks are just an invitation for contamination and bacteria.

According to the Food Poison Journal [4], two children were admitted to pediatric intensive care due to a botulism outbreak from canned chili sauce. The Castleberry Food Company issued a recall for three of its chili sauces after eight reported botulism cases. Its warehouse and manufacturing plant were immediately put under investigation, and the FDA found over 16 cans of contaminated chili sauce. During the investigation, they also found that many pieces of the food processing equipment were not properly maintained.

All food-industry companies follow guidelines put in place by the U.S. Food and Drug Administration (FDA), which includes adhering to strict welding schedules to ensure proper fabrication of all pipes and tubes necessary for the food processing operation. Ron Schmidt [2], contributing writer for Food Safety Magazine, says, “While it is not too difficult to protect the outside surface of a weld by using an inert gas as coverage, preventing oxidation and loss of corrosion resistance on the inside is often overlooked.”

What tools are recommended for Process Pipe Applications?

At Arc-Zone, we have assembled best of breed welding products that include: torches, front-end parts, and back purging equipment to ensure the job is done safely, with the focus on cleanliness and durability.

We recommend investing in purge gas equipment to avoid corrosion in stainless steel pipes. This equipment is highly effective to control gas flow and pressure, and is suitable for food-safe and multi-use applications [2]. There’s a wide offering of high purity welding equipment, such as purge baffles, purge dams, weld backing tape, trail shields, purge cups, and oxygen monitors.

References

[4] Falkenstein, D. (2015). The 2007 Castleberry Farms Botulism Outbreak. [FoodPoisonJournal.com Article]. Retrieved from http://www.foodpoisonjournal.com/foodborne-illness-outbreaks/the-2007-castleberry-farms-botulism-outbreak/#.WLcWEvnyvIU

[2] Fletcher, M. (2014). In the Food Plant: Danger of Corrosion When Welding Stainless Steel. [FoodSafetyMagazine.com Article]. Retrieved from http://www.foodsafetymagazine.com/enewsletter/in-the-food-plant-danger-of-corrosion-when-welding-stainless-steel/

[3] Graham, D. J. (2006). Snapshots in Sanitary Equipment: Developing an Eye for Hygiene. [FoodSafetyMagazine.com Article]. Retrieved from http://www.foodsafetymagazine.com/magazine-archive1/aprilmay-2006/snapshots-in-sanitary-equipment-developing-an-eye-for-hygiene/

[1] Sargento. (2017). Retail Products Affected by Expanded Recall. [Info.Sargento.com Information]. Retrieved from https://info.sargento.com/