You may know Arc-Zone’s Joanie Butler from the phone– she may have helped you put your welding supplies order together as part of our team, or she may have answered a technical welding question for you over email. When Joanie is not serving as Arc-Zone’s Pro Account Manager, she is working on her metal art. Joanie is known for taking scrap metal and turning it into amazing art. She has a fondness for critters, from dogs and owls to starfish and spiders. Check out her work on Instagram, you’ll be amazed.

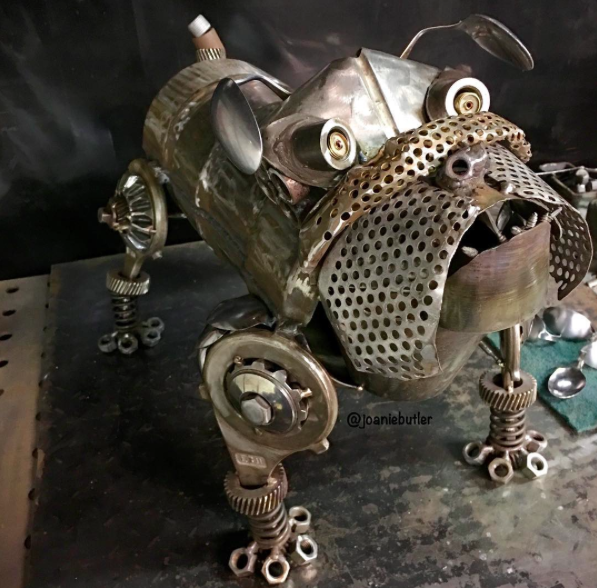

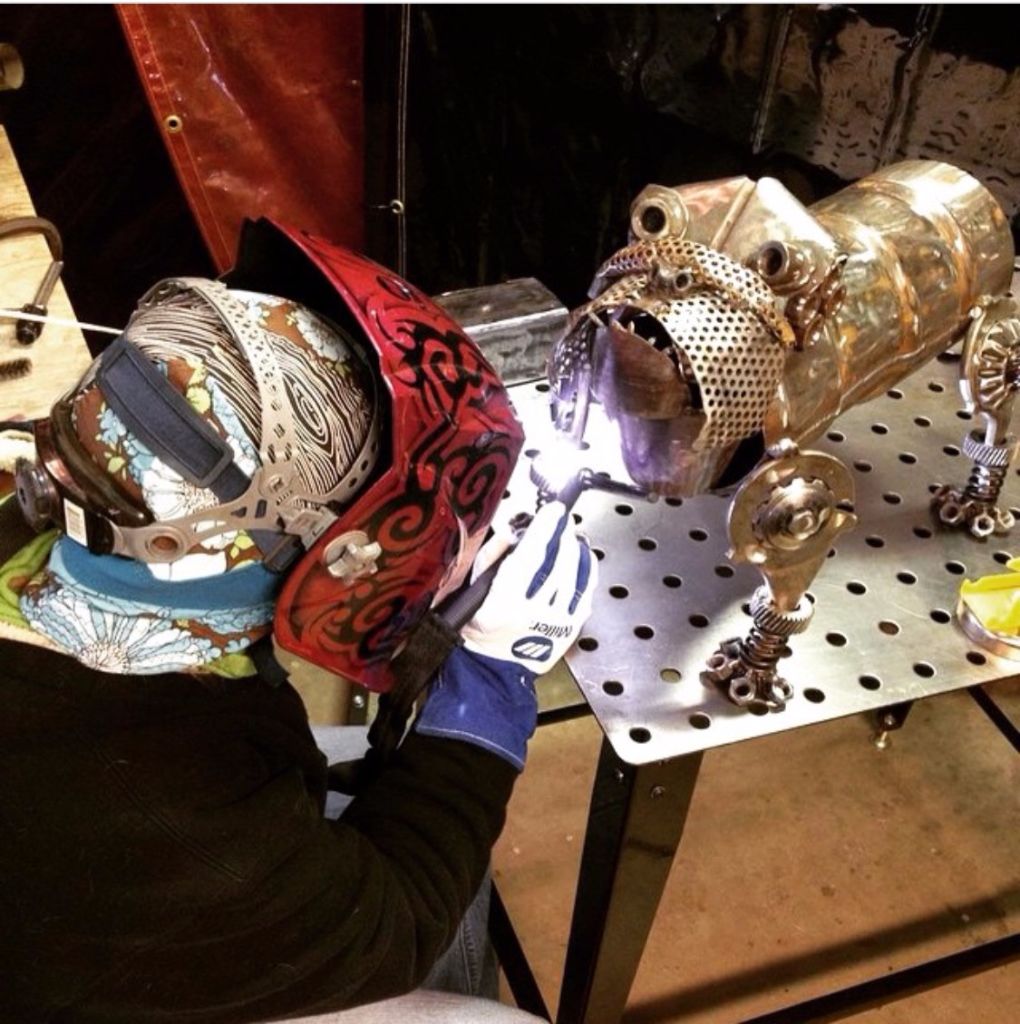

One of Joanie’s recent projects was welding up this little bull dog for Aaron Biefer, owner/operator of Bulldog Welding in Holly, Michigan (check out his work, @BulldogWelding on Instagram).

When Aaron challenged Joanie to recreate his four legged BFF #bulldog Owen back in January, she was so happy to honor a pet that was still alive. “I had absolutely no idea my own dog would be diagnosed with an incurable cancer just a little over a month into the build,” she says.

Knowing how difficult that time was for Joanie, Aaron made it a point to keep in contact with her almost daily. “For that I have no words other than a heart felt Thank You,” she says, noting that she has had so much support from the welding community online. “Amazing people come into your life when you need them the most,” she says.

Joanie says the bull dog (check out the photos on Instagram by searching for #abulldognamedoweniwillbe) is officially back on her building table and she’s looking forward to picking up where she left off.

* * *

We asked Joanie to tell us a bit about her process…. she says most of her metal comes from a collection she’s been growing for over 10 years. She’s built relationships with automotive repair shops, machine shops and motorcycle dealership service departments. Joanie says they have been generous with their scrap. “I’ve also developed a keen eye for industrial park’s unlocked dumpsters,” she says.

On Welding Scrap Metal

Working with scrap metals can be extremely hazardous to your health if you don’t take the necessary steps to prepare it and use proper the proper Personal Protection Equipment (PPE). This is especially important if you intend to cut, weld or grind the metal. Most automotive scrap (internal engine components like pistons, camshafts, crankshafts, gears, bearings, brake parts, suspension components, nuts, bolts etc.) are submerged in oil for the duration of their life. Metal is actually porous and like a sponge, soaks it up. it’s only when you add extreme heat (when welding, for example) will you pull the oil out of the pores of the metal. The oil bubbles out and oil can ignite–and you’ll have deadly fumes to deal with on top of a contaminated weld.

On Cleaning your Metal for Welding

First and Foremost Proper Safety First!! This is where PPE is extremely important! I always make sure I keep myself as safe as possible when i’m in metal prep mode. Safety glasses, gloves, and a respirator!

And a reminder: DO NOT USE BRAKE CLEANER!

If you want the textbook answer check out this article from Practical Welding Today, “Arc Welding 101: Cleaning material with brake cleaner before welding, a risky move that can turn deadly.”

The steps I take to clean and prep the material before assembly are critical to the final presentation of the piece. I take into consideration the previous life of the parts and pieces and prep accordingly. I have a laundry list of different tricks and techniques.

I do my best to steer away from chemical cleaners and stick with 90-99% rubbing alcohol to soak greasy or oiled scrap. I also use fire/heat to help burn out any oil that had been absorbed into some pieces. I also use an assortment of pneumatic grinders, electric grinders and dremel tooling to remove any remaining rust or surface contaminates.

It’s a very time consuming process that you hope pays off in the final product

Keep up with Joanie on her Instagram, and follow Arc-Zone for more great stories about the amazing welders we meet, the products we sell, and tips from our PRO Partners. We’re on Instagram, Facebook, YouTube, and Twitter.