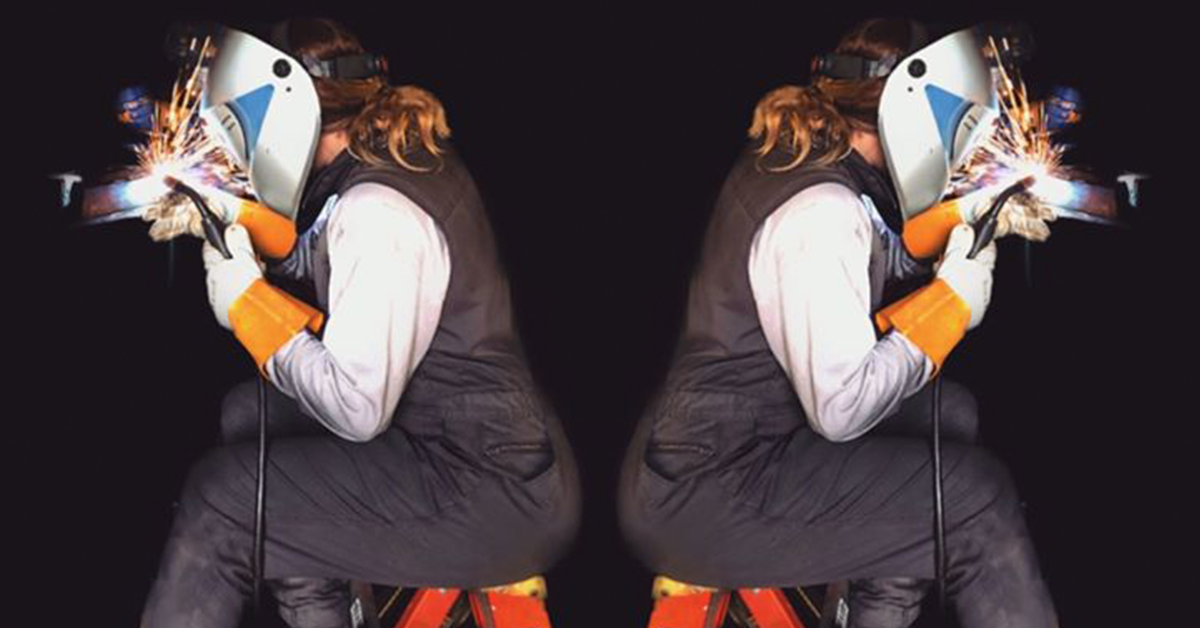

Modern day Rosie the Riveter, Andrea Leone shares her experience in the welding industry and where she sees the future of the trade.

Meet the woman who created a place to celebrate, discuss and provide resources for women in the welding industry.

Meet the women breaking the glass ceiling and paving the way for more women in the trades!

Learning to step out of the comfort zone into a more fulfilling and creative career […]

The fairytale to tell your kids We all know that saying, “If you can’t stand […]

How welding impacts your pregnancy or likelihood of becoming pregnant One of Carmen Electrode’s most […]

A brief encounter with metal artist, Sarah Stork We’ve been obsessed with Sarah Stork’s metal […]

The key to a fabricator’s success is incorporating little tricks and tools that improve both efficiency and weld quality.

Four years ago, Lena Dotson experienced welding for the first time. “I put a hood on, I picked up that gun and I laid down my first weld ever. As soon as I seen that spark, I fell in love with welding. Watching that puddle fill up was so satisfying to me.” That was then, so where is she now?

In honor of the passing of Rosalind P. Walter, one of the original Rosie’s, we’re […]

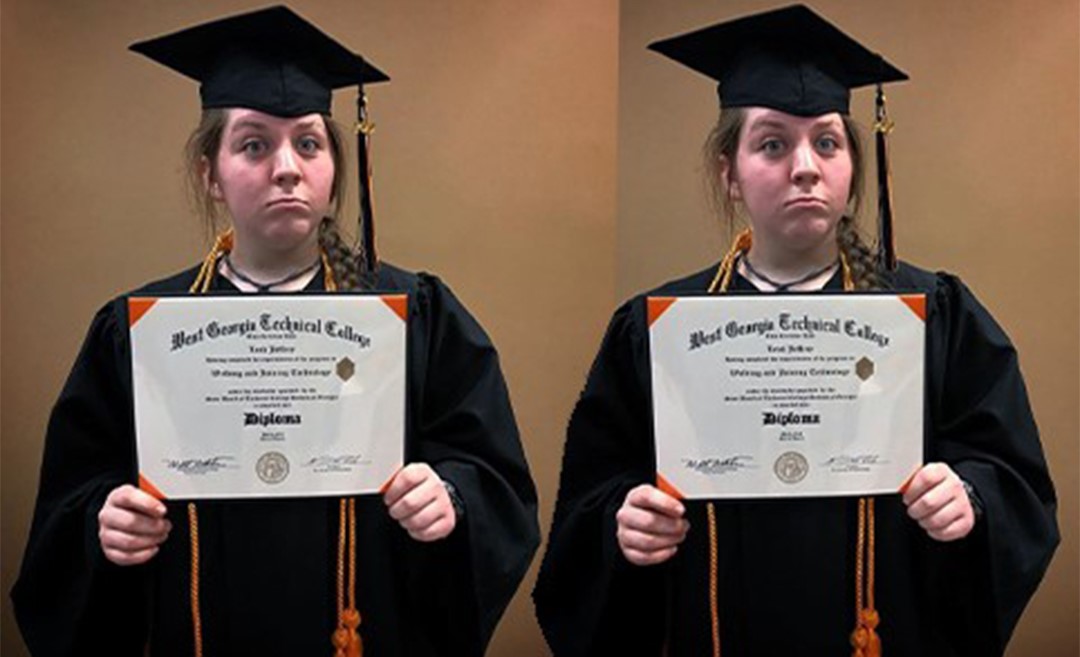

Love At First Sight We first met Leah Jeffery at the 2019 Fabtech Expo where […]

One of the core values of the Carmen Electrode brand is empowering women. We strive […]